Men’s health is in crisis.

A growing number of men are facing life with a prostate cancer diagnosis. Globally, testicular cancer is the most common cancer among young men. And across the world, one man dies by suicide every minute of every day.

We all know someone who will have struggled with one of these diseases, so help support and raise awareness for those who have or will be affected.

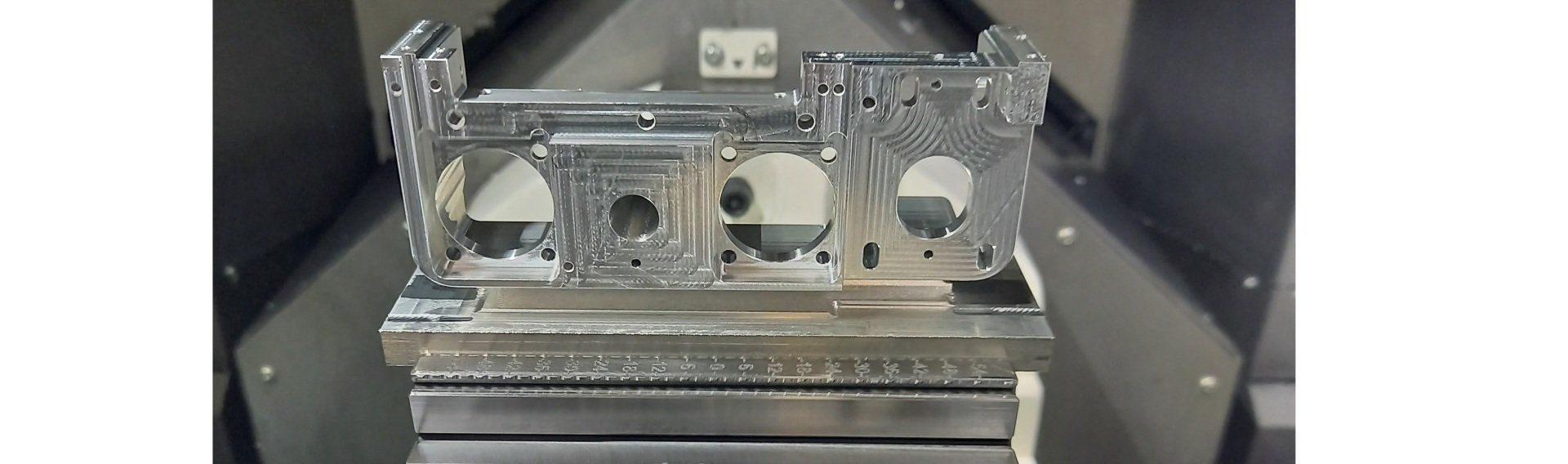

Our latest project is manufacturing Inconel 718 prototype components for the semi-conductor industry. Big thank you to the ISCAR projects team and everyone involved with the development of these parts.

Using the latest in ceramic cutting tool technology we have managed to half the time it takes to produce these parts (compared with the next best alternative). Inconel 718 (or Alloy 718) is a high-strength superalloy with a nickel-chrome base and is notoriously difficult to machine consistently and without experiencing strain hardening.

This particular

application involved Turning, Drilling, Milling and Thread Milling of small

deep non standard pitch threads and very tight machining limits of better than

5 microns (0.005mm) both dimensionally and geometrically.

By combining both our engineering know how and Iscar’s technical expertise this project was successfully concluded with a presentation to our client before handing over the resulting trial parts.

One such partnership we have is with ISCAR tools ltd. ISCAR is part of the IMC Group and one of the worlds leading suppliers of cutting tools.

Since 2018 a technical partnership has existed enabling us to work together developing machining and tooling strategies to reduce manufactures times whilst improving quality.

Read a recent article published in MTD CNC magazine:

http://read.mtdpublishing.com/march-2020/?page=22