Our modern manufacturing facility is equipped with the latest machinery and technology, enabling us to handle a wide range of projects across diverse industries. From aerospace to medical and automotive, our in-house capabilities ensure that we can meet the precise needs of each client.

We utilise state-of-the-art CNC machines for both turning and milling, delivering exceptional precision and repeatability across a wide range of materials. Our CNC machining capabilities are ideal for complex, high-tolerance components that require both skill and advanced technology.

Our advanced turning and milling services are designed to handle everything from simple to highly intricate parts, with tight tolerances and complex geometries. Whether it’s small batch runs or high-volume production, we deliver consistent, high-quality results.

We also offer precision grinding services, ensuring the finest finishes and tightest tolerances for parts requiring superior surface quality. Our grinding processes are ideal for components with intricate details and exacting standards.

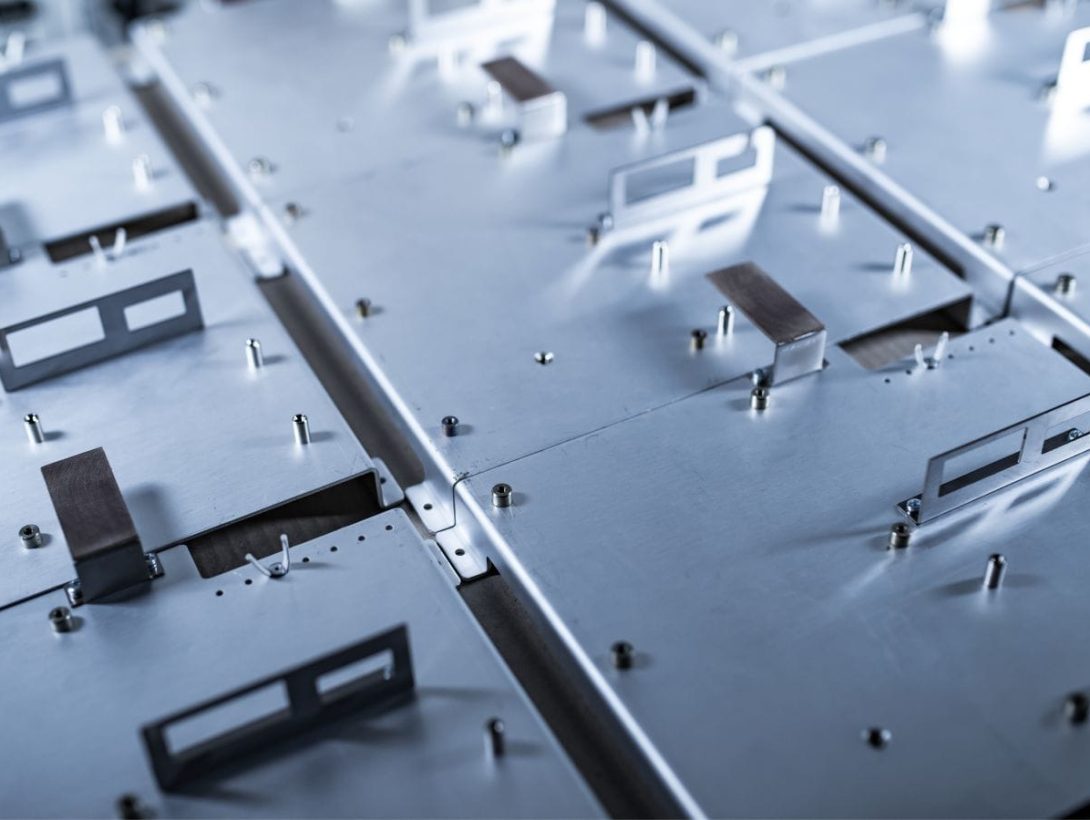

Our electro-mechanical assembly capabilities provide seamless integration of components into fully functioning systems. We specialise in complex assemblies, ensuring each part is perfectly fitted and functions as intended, with thorough testing at every stage.

With a focus on high tolerance machining, we guarantee precision across all our processes. Our climate-controlled environment ensures the stability and accuracy of every component, minimising the risk of material expansion or contraction, and maintaining the quality of parts throughout production.

Delivering high-accuracy, complex machined components and assemblies for aerospace, defence, medical, and advanced industries. With cutting-edge technology and a commitment to quality, we engineer solutions that meet the most demanding specifications.