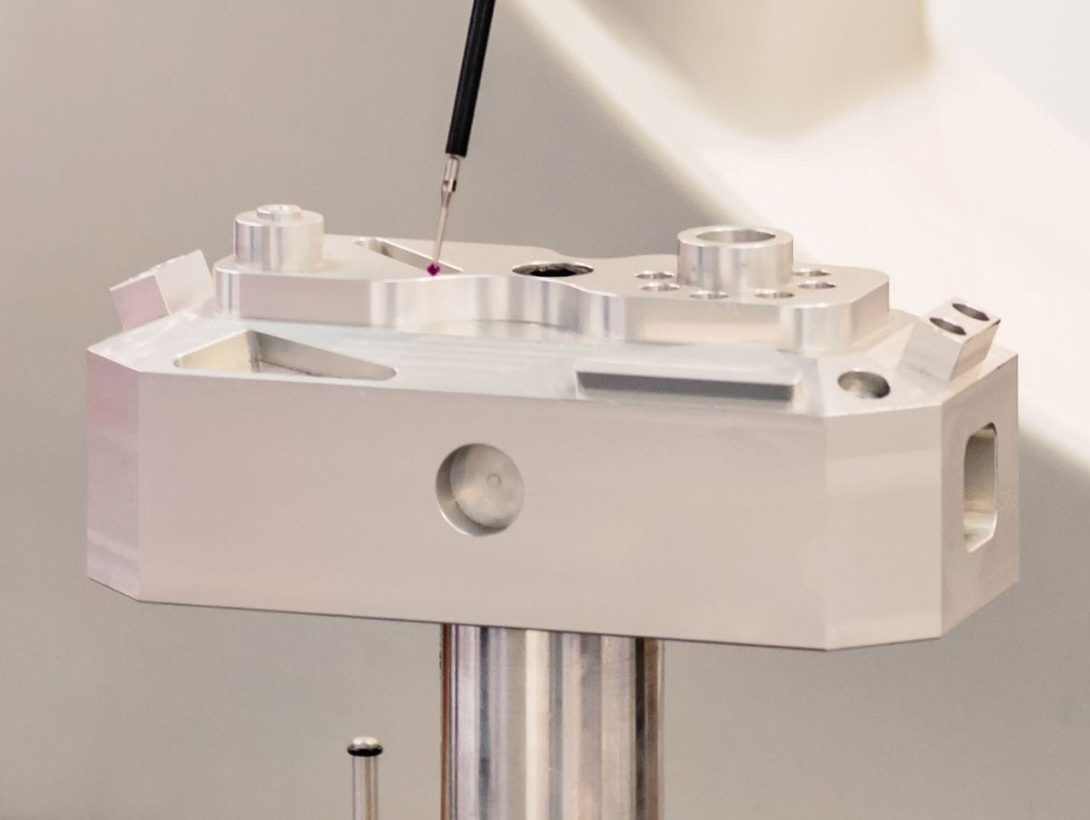

Our facility features 5-axis CMMs with offline programming, allowing for precise and efficient measurement of complex components. We also offer bespoke inspection solutions tailored to CTQ (Critical to Quality) requirements.

Every component is thoroughly checked to meet strict customer and industry standards. We utilise high-accuracy optical and visual inspection systems to verify intricate details, ensuring components meet exact specifications.

Operating in a temperature-controlled environment, we guarantee consistent and repeatable results. Our skilled inspection team also provides full FAIR (First Article Inspection Report) generation for complete traceability.

With a commitment to quality at every stage, our inspection department ensures precision, reliability, and compliance with the most demanding standards.