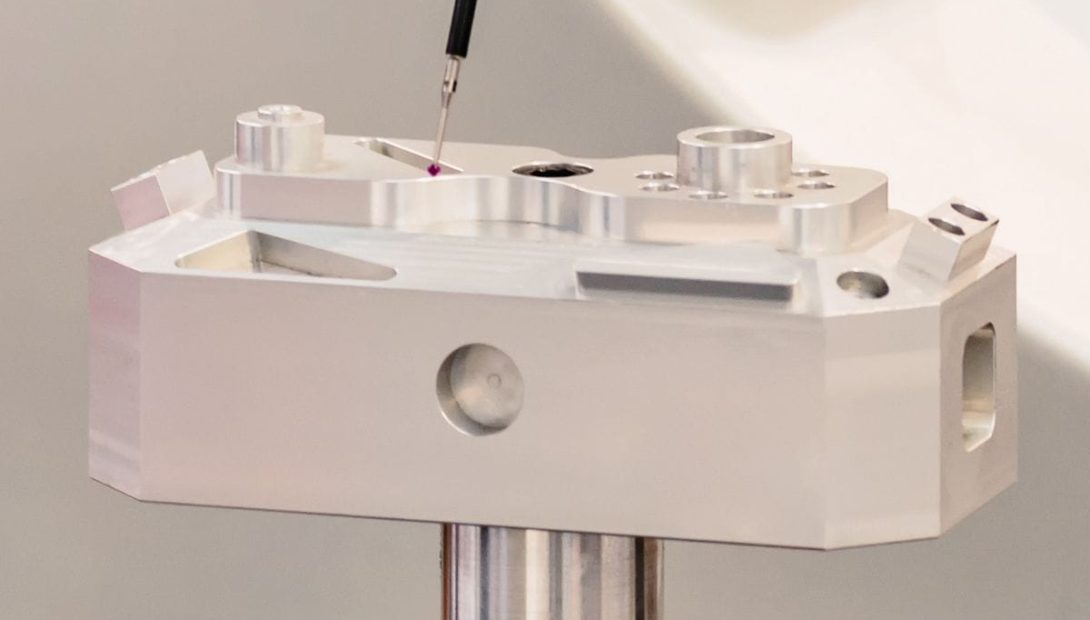

Our advanced machining capabilities include 5-axis CNC milling, turning, and grinding, allowing us to produce complex, high-tolerance parts with efficiency and accuracy. In assembly, we provide electro-mechanical builds, ISO Class 7 cleanroom assembly, and comprehensive testing, ensuring reliability and performance. Our inspection department utilises state-of-the-art CMMs, optical measurement, and bespoke verification processes to maintain the highest quality standards.